VCI COATINGS

VAPPRO® 837 WATER BASED VCI CORROSION INHIBITOR

VAPPRO 837 is a colorless water-based vapor corrosion inhibitor specially developed to replace conventional oil inhibitors.

Vappro 837 has excellent corrosion inhibition properties for combating corrosion on copper, steel, brass, and iron. The vapor phase inhibitors in Vappro 837 migrate and envelope metal surfaces with corrosion protection ions.

Coils, stacks and sheet metal protected by Vappro 837 are always ready for use. There is no cleaning or degreasing required on metals that are protected by Vappro 837 (minimizing trade effluent discharge).

Protected metal will retain a rust-free and clean surface without affecting the paintability, conductivity properties or appearance of the metal.

Vappro 837 does not interfere with sensitive lithographing or painting processes of the protected metal.

VAPPRO® 855 Anti-corrosion Oil

VAPPRO 855 is a light brown anti-corrosion oil blended with solvent. It is a mobile liquid possessing excellent water displacement properties. On evaporation of the solvent, it deposits a soft film, which provides a high degree of protection.

Vappro 855 is a multi-purpose de-watering fluid which provides an excellent protective film. Classified as a medium-term protective, it is used for a variety of purposes in machine shops and in heavy machinery. It is ideal for treating machine tools.

Vappro 855 offers perfect protection during storage periods. It is also recommended for the protection of sheet metal panels, where the residual greasy film serves as a mild press-working lubricant.

VAPPRO® 865 VCI CONFORMAL COATING

VAPPRO 865 is an oil-based thixotropic VCI corrosion inhibitor rust coating. This VCI coating is highly resistant to salt water, making it particularly useful in marine, industrial, and off-shore rust proofing applications.

VAPPRO 865 is most commonly used to undercoat vehicles and other heavy equipment. It provides optimal corrosion protection for up to 24 months for ferrous and non-ferrous metal exposed to outdoor environments.

VAPPRO® 868 VCI WAX COATING

VAPPRO 868 is a dark brown thixotropic liquid with VCI corrosion inhibitors and oil-based or solvent based carriers. The residual film, after solvent evaporation, is highly resistant to salt water and salt spray, making

Vappro 868 particularly useful in marine, industrial, and off-shore rust proofing applications.

Vappro 868 provides optimal corrosion protection for up to 24 months for ferrous and non-ferrous metals exposed to outdoor environments.

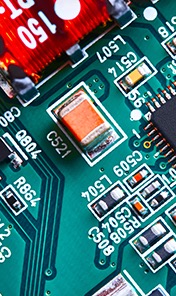

VAPPRO® 870CB VCI ELECTRO-SPRAY

VAPPRO 870CB is specially engineered for protecting printed circuit boards from corrosion, in electrical and electronic systems.

VAPPRO 870CB Electro-Spray’s dual functionalities simplify the maintenance of electrical and electronic systems. It cleans and protects in one application.

VAPPRO 870CB Electro-Spray is made of premium quality electrical contact cleaners fortified with specialty electronic corrosion inhibitors know as VAPPRO VCI. It eliminates galvanic corrosion commonly found in electrical systems and is extremely effective in protecting silver components from corrosion in Printed Circuit Boards.

VAPPRO 870CB is known to enhance manual and robotic soldering processes. It is packaged in a spray bottle that atomizes the liquid for effective application.

VAPPRO 870CB Electro-Spray does not contain any ozone-depleting substances.

VAPPRO® 886 Acrylic Coating

VAPPRO 886 is a water-based corrosion inhibitor developed as a complete replacement for oil-based rust preventives. Its aqueous solution is heat stable.

VAPPRO 886 is designed to be removed with conventional alkaline cleaners but it can be coated over with paints and primers without removal.

VAPPRO 886 is a non-toxic VCI water-based corrosion inhibitor specially developed to replace conventional, toxic oil-based rust preventives.

VAPPRO 886 is made from an Acrylic Copolymer emulsion with a mixture of non-toxic organic inhibitors. The formulation offers unprecedented advancement in outdoor corrosion protection. It successfully provides up to 24 months of protection in harsh, outdoor unsheltered protection.

VAPPRO 886 is non-flammable, weldable, biodegradable and has excellent salt spray resistance. It provides a fast drying, clear coating with a non-flammable protective barrier that allows visual inspection of the metal surface after application.

VAPPRO® 888 S-Kote

VAPPRO 888 S-Kote is a black viscous coating, specially developed to protect deck steam lines, steam valve manifolds, exhaust manifolds, exhaust pipes and windlass steam chests from corrosion on ocean vessels.

VAPPRO 888 S-Kote is made of a proprietary water-based emulsion copolymer, a non-toxic Magna GX-Additive, a proprietary heat resistant additive, and VCI additives. The Polymer used in S-Kote conforms to FDA CFR-21 Parts: 175.105,175.300,176.170,176.180 and is non-EEC–legislation under EINECS Registration (Europe).

It has high heat resistant with excellent UV and water displacement properties. VAPPRO 888 S-Kote withstands higher temperatures for longer periods than any other similar product and drastically reduces repair and maintenance cost. It is easily applied by brush and requires only minimal surface preparation. When applied to cold surfaces, it will dry to the touch within 3 hours after application. When applied to hot surfaces, it will skin over within 1 hour (this method is not generally recommended, as it is not possible to achieve the required minimum film thickness).

VAPPRO® 889 PEELABLE COATING

VAPPRO 889 is an environmentally-friendly water-based VCI Peelable Coating. It is a viscous liquid that provides excellent protection.

VAPPRO 889 provides long-term protection to both ferrous and non-ferrous metals. It also provides a transparent, or transparent light blue coating to high polished metals for easy visual inspection.

It can be easily removed with an alkaline detergent such as VAPPRO 800 VCI Cleaner or Magna M-100 Hard Surface Cleaner.

VAPPRO® 900 VCI ELECTRICAL INSULATOR

VAPPRO 900 quickly seals, insulates, waterproofs and protects electrical motors, printed circuit boards, and electronic components.

Vappro 900’s clear VCI coating allows visual inspection of insulated parts. It provides excellent protection in harsh and corrosive environments such as acids, alkalines, saline solutions, and solvents.

Vappro 900 dries to a flexible, tough, oil-proof film that protects electrical equipment. It is specially formulated from Isophthalic alkyd for durable chemical resistant finishes and excellent electrical properties. Complies with BS5629 and IEC85. In thin film applications, it dries rapidly. Vappro 900 is compatible with most insulating systems.

VAPPRO® 9837 WATER BASED VCI RUST INHIBITOR

VAPPRO 9837 is a water-based VCI Rust Inhibitor specially developed to replace conventional oil-based corrosion inhibitors.

VAPPRO 9837 has excellent corrosion inhibition properties for combating corrosion on copper, steel, brass, and iron.

VAPPRO 9837 is a free-flowing brownish liquid. It turns clear when dry on metal substrates. It leaves behind a thin layer of slightly tacky corrosion inhibition film which provides excellent corrosion protection.

VAPPRO 9837 can be easily removed with any water-based degreaser.

VAPPRO® VMC – Marine Coat

VAPPRO VMC is a solvent based brown thixotropic liquid corrosion inhibitor. The residual film after solvent evaporation is highly resistant to salt water and salt spray. It, therefore, makes VAPPRO VMC particularly useful in marine, industrial, and offshore rust proofing applications.

VAPPRO VMC provides optimal corrosion protection and UV resistance for up to 24 months for ferrous and non-ferrous metals exposed to challenging outdoor environments.

VAPPRO® Rubberplast

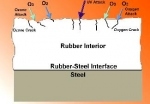

One of the most common problems that deter operational readiness of military equipment and vehicles is the premature aging of rubber parts. All exposed rubber parts are vulnerable to atmospheric oxygen, ozone and UV attacks. The oxygen, ozone and UV attacks will cause cracks on the rubber surface which in turn will lead to degradation. The cracks will propagate deeper into the rubber part and will eventually result in mechanical failures like compression set and creep.

VAPPRO Rubberplast is specially developed to combat premature aging of rubber and plastic parts used in military vehicles and equipment.

VAPPRO Rubberplast is a free-flowing proprietary silicone emulsion liquid with excellent adhesion properties to rubber and plastic. Rubber and plastic parts that are treated with VAPPRO Rubberplast exhibit a high reflective index which is a critical factor in combating harmful UV and ozone.

VAPPRO Rubberplast is an ideal conditioner for plastics and rubbers such as nitrile rubber (acrylonitrile, acrylonitrile butadiene, nitrile-butadiene rubber, NBR), buna rubber, neoprene, polychloroprene, butyl and silicone rubber and Viton (fluoroelastomers).

VAPPRO® TRC

VAPPRO TRC is an oil-based thixotropic vapor rustproofing coating. This VCI coating is tested to ASTM B117 Salt Spray Test and is highly resistant to salt water. It makes VAPPRO TRC extremely effective in rust proofing all types of automotive vehicles.

VAPPRO TRC is specifically engineered to withstand extreme corrosive environments such as road salts and other corrosive materials. It can also be used for marine, industrial, and offshore rustproofing applications.

VAPPRO TRC can also be used for coating heavy equipment. It provides optimal corrosion protection for 24-36 months on ferrous and non-ferrous metal exposed to outdoor environments.